(L2-2611) On-line characterization of fluids for the metal-processing industry

As part of the application project, we will face some of the challenges of fluid characterization in the metal-processing industry. Our research will focus on the following three areas of measurements:

a) The emulsion concentration

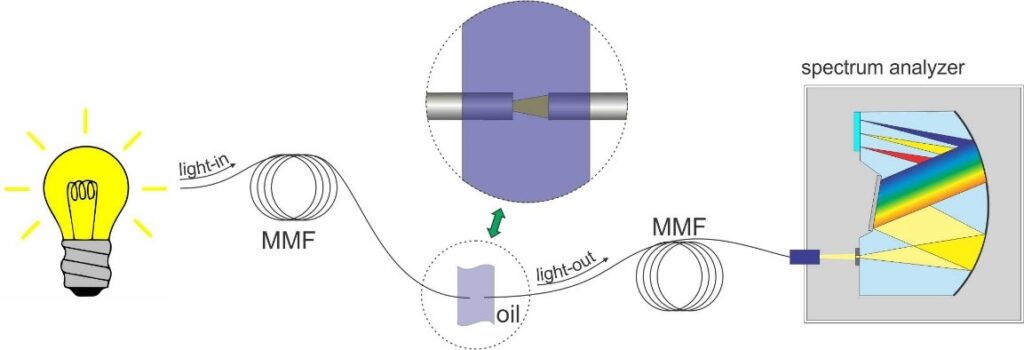

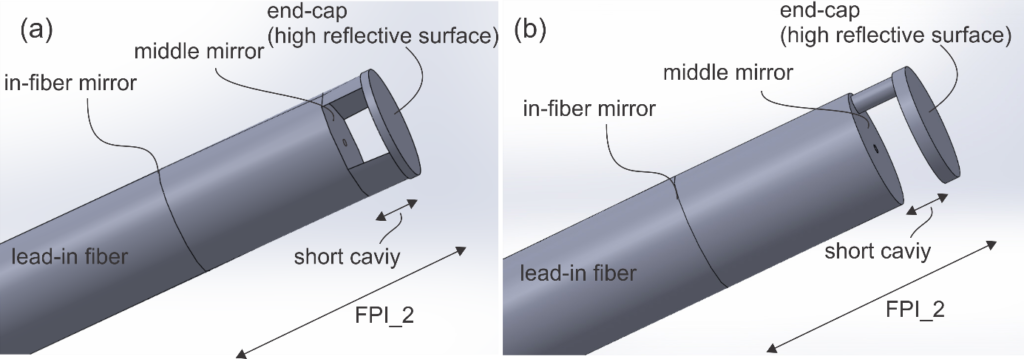

Within the project, we would like to research and develop a compact and robust Refractive Index (RI) sensor for on-line emulsion concentration measurements in the metal processing industry. We intend to rely here on fiber optic sensing technology, which can provide robust and compact solutions, suitable for use in industrial environments. There are considerable research and development challenges that need to be solved before optical fiber-based RI sensors could be implanted reliably under conditions encountered in metalworking emulsions.

Fig. 1 Short cavity micro-cells.

a-1) Project results:

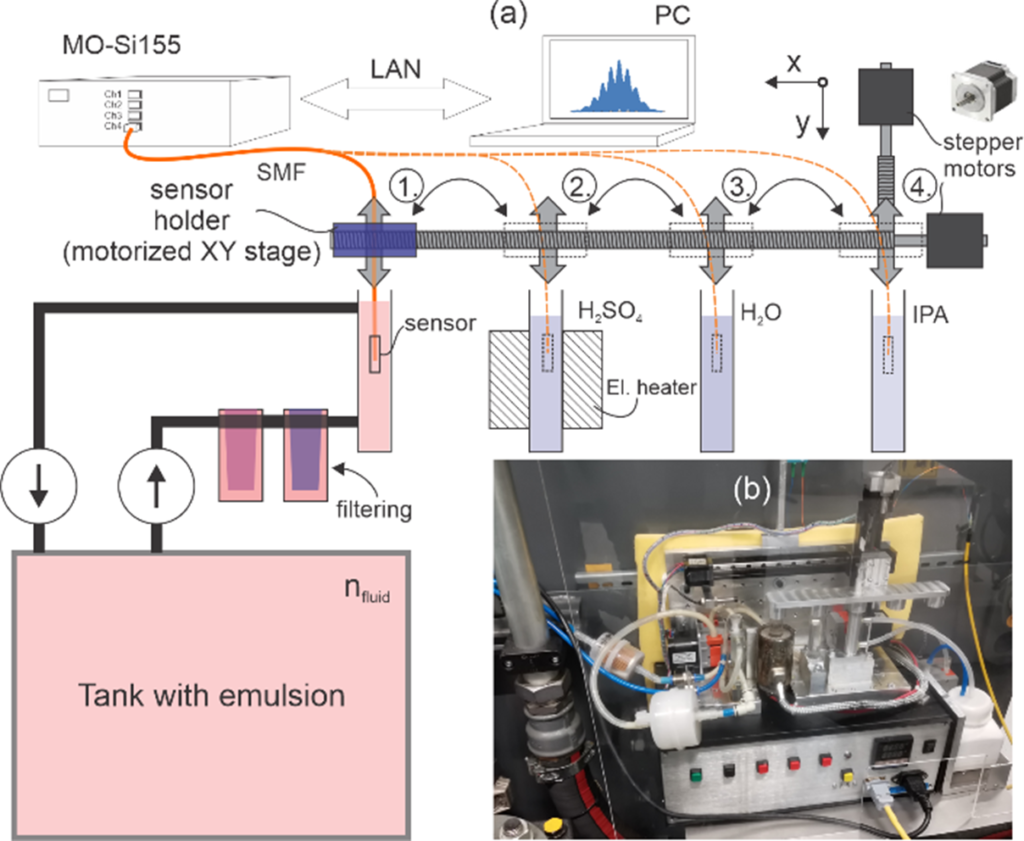

An on-line emulsion concentration sensor based on an optical fiber refractometer has been developed. The meter is installed in the industrial plant of Marovt in Slovenska Bistrica, where continuous measurements of the emulsion of the CNC machine tool are continuously performed and archived. The measuring system has been installed at Marovt for more than 2 years. Results were recently published in following paper:

Results were recently published in following paper: • Pevec, S., Kunavar, J., Budinski, V., Njegovec, M., and Donlagic, D., "An All-Fiber Fabry-Perot Sensor for Emulsion Concentration Measurements," Sensors-Basel 23(2023).

Link to the paper: https://doi.org/10.3390/s23041905

The whole system is schematically presented in Fig. 2, with photo of the system taken in Marovt d.o.o. facility.

b) Monitoring of industrial anodization baths

Online chemical analysis of the anodizing bath as one of the major challenges and problems that they would like to address in the future. There is a great need for on-line monitoring and automatic dosing of bath components, especially on the final steps of the anodizing process, to measure and control the sealing and coloring processes.

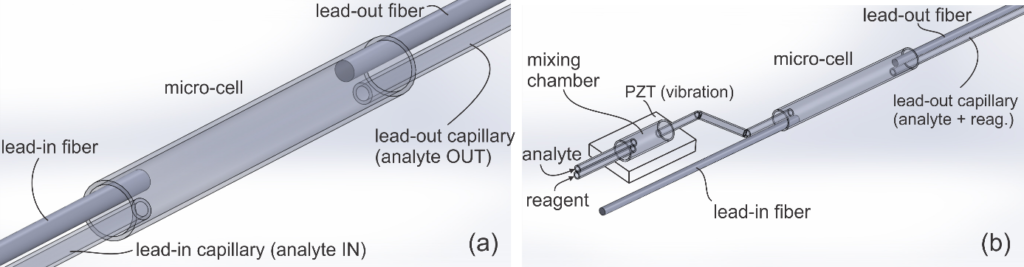

We expect to deliver a sensor system based on spectral absorption/color measurement, using a specially designed micro-cell. Regarding the small-dimensions, the use of analyte and reagents is minimized, which contributes to money-saving and reducing the environmental pollution.

Fig. 3 Micro-cell based sensor for: (a) Direct spectral absorption measurement, (b) Indirect spectral absorption measurement for fluoride detection.

b-1) Project results:

The on-line absorption dye meter "Dark inox" shown in the Fig. 4 has been developed. The meter is installed in the industrial plant of Aluminium Kety Emmi d.o.o. in Slovenski Bistrica.

In recent months we have managed to store long-term measurement traces which already show some trends and correlations with the dye consumed, but we do not have enough data to draw any final conclusions at the moment. Once the batches are completed at the beginning of 2023, we will be able to analyse the results in more detail and draw conclusions on the remaining amount of dye in the bath.

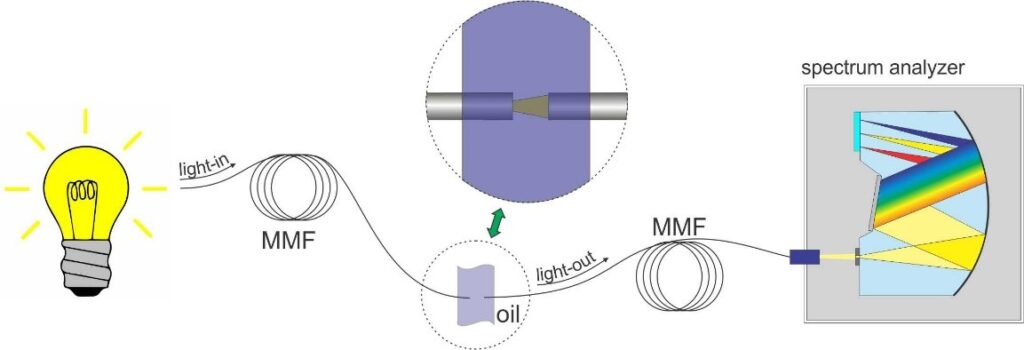

c) Monitoring of industrial anodization baths

We intend to employ optical fiber sensor technology for oil contamination monitoring. This might have additional advantages, as fiber sensor technology can offer compact solutions with dimensions of the sensor probe in the range of 125 m, which allows installation of the sensor in the harsh environments at the near proximity of contamination sources, (rotating shafts, bearings, etc.). This could contribute to early detection of faults of critical machine components. Optical fiber sensor technologies also provide many other advantages, by allowing measurements in aggressive-harsh conditions, such as high temperatures, high pressures, acidic/base environments, electromagnetic and radioactive contaminated environments. The proposed sensors, with their advantages, will thus enable not only optimum available oil exploitation and machine protection, but also strong support for indirect monitoring of the health of critical components in mechanical systems.

Fig. 5 Experimental setup for oil contamination measurement based on spectrum analysis.

Project management:

WP1. Project managing - a web page with a general description of this project will be prepared.

WP2. Preparation of the conceptual design and sensor production for: On-line optical characterization of oil in water emulsion, on-line characterization of fluids needed for aluminum surface treatment, and on-line characterization of lubrication oils.

WP3. Proof of concept using a fiber-optic, short cavity micro-cell sensor installed in a machine tank.

WP4. Proof of concept using a fiber-optic/capillary micro-cell sensor for anodizing bath fluid characterization.

WP5. Proof of concept using an absorption micro-cell for lubrication oil contamination detection.

WP6. Adaptation of the absorption micro-cell sensor system to a real environment for real-time measurements.

WP7. Systematic measurements of a sensor`s response to different process actions (refilling the emulsion, concentration balancing, etc.)

WP8. Optimization of sensor systems and cost-optimization.

Duration of project: 1.9.2020 – 31.8.2023

Project lead: doc. dr. Simon Pevec

Participating research organizations and researchers:

University of Maribor, Faculty of electrical engineering and computer science:

– doc. dr. Simon Pevec (SICRIS)

– red. prof. ddr. Denis Đonlagić (SICRIS)

– doc. dr. Matej Njegovec (SICRIS)

– asist. dr. Vedran Budinski (SICRIS)

– doc. dr. Bojan Gergič (SICRIS)

Co-financiers:

Marovt d.o.o. http://www.marovt.com/

Aluminium Kety Emmi d.o.o https://www.emmi.si/