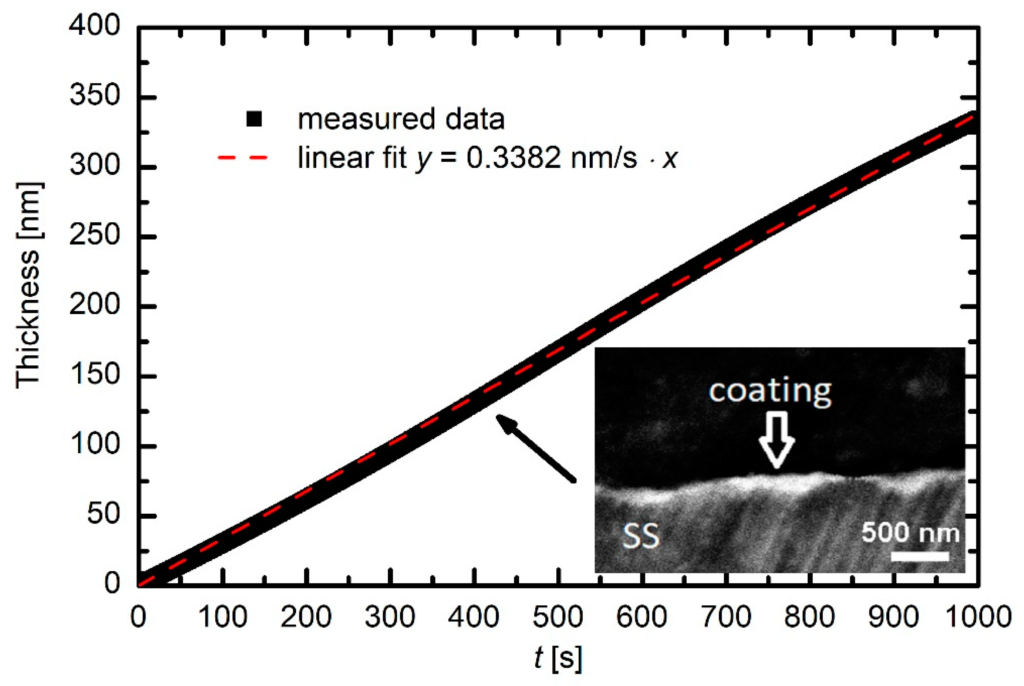

An industrial size plasma reactor of 5 m3 volume was used to study the deposition of silica-like coatings by the plasma-enhanced chemical vapor deposition (PECVD) method. The plasma was sustained by an asymmetrical capacitively coupled radio-frequency discharge at a frequency of 40 kHz and power up to 7 kW. Hexamethyldisilioxane (HMDSO) was introduced continuously at different flows of up to 200 sccm upon pumping with a combination of roots and rotary pumps at an effective pumping speed between 25 and 70 L/s to enable suitable gas residence time in the plasma reactor. The deposition rate and ion density were measured continuously during the plasma process. Both parameters were almost perfectly constant with time, and the deposition rate increased linearly in the range of HMDSO flows from 25 to 160 sccm. The plasma density was of the order of 1014 m−3, indicating an extremely low ionization fraction which decreased with increasing flow from approximately 2 × 10−7 to 6 × 10−8. The correlations between the processing parameters and the properties of deposited films are drawn and discussed.

Materials 2019, 12(19), 3238; https://doi.org/10.3390/ma12193238